OMC Service and Repair Manuals for Inboard Stern Drive Outdrives

Item Details For use with all Stringer 400 / 800 (4cyl / V6 / V8 2.5L 120hp, 3.0L 140hp, 3.8L, 4.3L, 5.0L 305, 5.7L 350 outdrives 1982-1986 1978-1981 Used a completely different housing & shift cable that operated in the complete opposite manner, so please don't mix these up as these are in no way interchangeable. Omc 400 outdrive get yourself a manual on OMC sterndrives. RJ Current Boat 1-800-914-1123 001-801-571-0071 (International Calls) omc 800 sterndrive manual - free pdf ebook omc 800 sterndrive manual at greenbookee.org OMC STERNDRIVECOBRA 80 90 120 (400 Series) 140 (400 Series) 155 165 185 200 210 215, 225, 230 230.

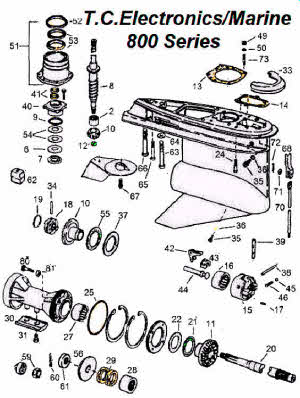

A copy of the original OMC Manual in pdf format is included as well a Seloc hard copy manual that comes with the boat. 1986 - 1998 OMC Sterndrive Manual PDF - ORIGINAL sunbirdcorsair 1992sunbirdcorsair@gmail.com. Fits: OMC Sterndrive Lower Unit 800 Series OEM #987242 Remanufactured 1 Year Warranty Outdrives rebuilt by Certified Mechanics OEM Parts. Price=$1,595 plus $250 refundable core.= $1,845.See our Core Policy for details on how to recycle your core & receive your core deposit back.

OMC Stern Drive Outdrives

OMC Stern Drive 1964-1986 Repair Manual

- OMC Stringer Outdrive 'electric shift' 1962-1977

- OMC 400 Series Outdrive 'hydraulic shift' 1978-1981

- OMC 800 Series Outdrive 'hydraulic shift' 1978-1981

- OMC 400 Series Outdrive ‘mechanical shift'1982-1985

- OMC 800 Series Outdrive ‘mechanical shift'1982-1985

OMC Cobra Stern Drive 1986-1998 Repair Manual

- OMC Cobra Outdrive 1986-1993

- OMC King Cobra 1987-1989 for 7.4 and 7.5 liter engines

- OMC Cobra / Volvo SX - Outdrives 1993-1998

- OMC / Volvo Penta 'Joint Venture' 'Cone Clutch'

OMC Sterndrive Outdrives

OMC Stern Drives 1964-1986 Repair Manual

- OMC Stringer Outdrive 'electric shift' 1962-1977

- OMC 400 Series Outdrive 'hydraulic shift' 1978-1981

- OMC 800 Series Outdrive 'hydraulic shift' 1978-1981

- OMC 400 Series Outdrive ‘mechanical shift'1982-1985

- OMC 800 Series Outdrive ‘mechanical shift'1982-1985

574 pages, .pdf format Teleprompter app for macbook.

USD Price: $19.98

Digital .pdf Delivered By Download Link

OMC Stern Drives 1986-1998 Repair Manual

With it, you can download and record music from over 3000 music websites. There are millions of users of this ID3 tag. The music that you can download is of very high quality and are 100% original.

- OMC Cobra Outdrive 1986-1993

- OMC King Cobra 1987-1989 for 7.4 and 7.5 liter engines

- OMC Cobra / Volvo SX - Outdrives 1993-1998

- OMC / Volvo Penta 'Joint Venture' 'Cone Clutch'

616 pages, .pdf format

USD Price: $19.98

Digital .pdf Delivered By Download Link

OMC Stringer Stern Drive Tilt System

- Introduction

- Electrical Description

- Mechanical Description

- Troubleshooting

- Electrical Schematic

- Power Tilt Modifications

- Part Numbers & Descriptions

10 pages, .pdf format

USD Price: $4.98

Digital .pdf Delivered By Download Link

OMC 400 Stern Drive Parts Catalog Rc track design software, free download.

- OMC 400 Series

- Models 120, 140

- Pages: 69

- Exploded Parts Diagrams

- Scanned Document

- .pdf format

USD Price: $4.98

Digital .pdf Delivered By Download Link

OMC Stern Drive Parts Catalog

- OMC / Volvo Penta

- Pages: 178

Models:

- Stringer

- Cobra

- Cobra SX

- Volvo Penta

download free ⇨

Reference Sources: OMC Stern Drive Parts Diagrams; OMC Outdrive Model Identification; OMV Sterndrive Repair Videos

OMC Sterndrive Outdrive History

OMC stern drives were produced by the Outboard Marine Corporation from 1962 until the end of 1992.

OMC Stringer 1962-1977

The OMC Stringer was produced from 1962-1977 when they discontinued production and manufacturing of the – Electric shift model.

OMC 400/800 Hydraulic Shift 1978-1981

In 1978 the Stringer model upper gear housing design was coupled with a completely redesigned lower unit. This new design would call for a sliding clutch dog in the lower unit which would engage and lock into forward or reverse gears. This clutch was manually engaged by the use of a shift cable which contained 2 inner cores for forward and reverse. These new models were called the 400 series (4 cylinder engines) and the 800 series (6 cylinder, V6 and 8 cylinder V8 motors). Early models manufactured between 1978 and 1981 used a hydraulic oil pump in the lower unit to assist the mechanical shift cable with engaging the clutch dog into gear.

OMC 400/800 Mechanical Shift 1982-1985

In 1982, engineers redesigned the lower unit to shift with a mechanical shift cable and the hydraulic shift assist pump was removed. These new units were still called the 400 and 800 series models – but were widely referred to as the ‘mechanical shift' models. This version of the 400 and 800 series were produced up to the year 1985.

OMC Cobra 1986 to 1993

OMC completely re-engineered their outdrives in 1986 and introduced the Cobra model. These new models were available in a variety of motor options; including a 2.3L Ford 4 cylinder (1986-1987), 3.0L Chevy, 5.0L – 5.7L – 5.8L Ford and Chevy small block V8's and the monster 7.5L 460 Ford big block V8 (1987-1988 King Cobra). The new models now used the modern u-joint style drive system.

The early Cobra models had some problems keeping the clutch engaged into the gear in certain instances due to a 3 degree undercut on the top of the clutch dog tooth. The clutch was updated to a 5 degree undercut, and a shift interrupter switch was added along with an updated design for the shift detent.

OMC Cobra / Volvo SX 1993-1998

In 1993 OMC and Volvo entered into a joint venture and began producing a hybrid stern drive. This new design used the OMC Cobra transom plate assembly but was all Volvo engineering beyond that point. This included the Volvo cone clutch outdrive design and heavier duty shifting components which eliminated the clutch dog system. This new system was sold as the Cobra by OMC, and the SX by Volvo. With the introduction of this OMC Cobra/Volvo SX sterndrive hybrid model, also referred to as the ‘cone clutch', the last of the OMC designed sterndrives finished production in 1992.

OMC Outboard Motor Corporation officially went out of business in 1998 when Volvo purchased the rights and their manufacturing facility in Lexington. OEM parts are still being manufactured through BRP (Bombardier Recreational Products). Many OEM parts are still interchangeable with Johnson and Evinrude outboard models; and some outboards still use the identical lower housing as the Cobra model.

Omc 800 Drive

By Doug Alling

Keeping your sterndrive in tip-top shape will add years to its life — and help to keep your boat afloat.

Omc Outdrive Parts Diagram

Giving your sterndrive some attention now can prevent major problems later. (Photo: Volvo Penta)

Sterndrives were first commercially introduced in the early 1960s, and came to dominate the boat propulsion market in short order. The biggest names in the sterndrive game today are Mercury and Volvo with thousands of older Outboard Marine Corporation (OMC) drives still in use but no longer being produced.

When you power up your engine and pull away from the dock, you set in motion a lot of activity at the stern of your boat. You push the throttle, engaging the prop. Power from your engine is transferred to the sterndrive via the drive shaft. Exhaust is pushed from the engine and exits at your prop. All of these functions start inside your boat and end at the sterndrive and require holes through the transom of your boat, at or below the waterline. Three to be exact: One for the throttle cable, one for the drive shaft, and one for the exhaust. And there's only one thing that keeps the water outside the boat from entering those openings — the sterndrive's bellows, those black corrugated rubber things that are clamped to the boat's transom and sterndrive in a place that makes them really hard to see. Perhaps the old saying, 'out of sight, out of mind,' is why bellows become such a big issue when it comes to sinkings. Take away the biggest and most obvious cause of boat sinkings at the dock — hurricanes — what do you think comes in second place? If you guessed sterndrive bellows failures, take a bow.

- OMC Cobra Outdrive 1986-1993

- OMC King Cobra 1987-1989 for 7.4 and 7.5 liter engines

- OMC Cobra / Volvo SX - Outdrives 1993-1998

- OMC / Volvo Penta 'Joint Venture' 'Cone Clutch'

616 pages, .pdf format

USD Price: $19.98

Digital .pdf Delivered By Download Link

OMC Stringer Stern Drive Tilt System

- Introduction

- Electrical Description

- Mechanical Description

- Troubleshooting

- Electrical Schematic

- Power Tilt Modifications

- Part Numbers & Descriptions

10 pages, .pdf format

USD Price: $4.98

Digital .pdf Delivered By Download Link

OMC 400 Stern Drive Parts Catalog Rc track design software, free download.

- OMC 400 Series

- Models 120, 140

- Pages: 69

- Exploded Parts Diagrams

- Scanned Document

- .pdf format

USD Price: $4.98

Digital .pdf Delivered By Download Link

OMC Stern Drive Parts Catalog

- OMC / Volvo Penta

- Pages: 178

Models:

- Stringer

- Cobra

- Cobra SX

- Volvo Penta

download free ⇨

Reference Sources: OMC Stern Drive Parts Diagrams; OMC Outdrive Model Identification; OMV Sterndrive Repair Videos

OMC Sterndrive Outdrive History

OMC stern drives were produced by the Outboard Marine Corporation from 1962 until the end of 1992.

OMC Stringer 1962-1977

The OMC Stringer was produced from 1962-1977 when they discontinued production and manufacturing of the – Electric shift model.

OMC 400/800 Hydraulic Shift 1978-1981

In 1978 the Stringer model upper gear housing design was coupled with a completely redesigned lower unit. This new design would call for a sliding clutch dog in the lower unit which would engage and lock into forward or reverse gears. This clutch was manually engaged by the use of a shift cable which contained 2 inner cores for forward and reverse. These new models were called the 400 series (4 cylinder engines) and the 800 series (6 cylinder, V6 and 8 cylinder V8 motors). Early models manufactured between 1978 and 1981 used a hydraulic oil pump in the lower unit to assist the mechanical shift cable with engaging the clutch dog into gear.

OMC 400/800 Mechanical Shift 1982-1985

In 1982, engineers redesigned the lower unit to shift with a mechanical shift cable and the hydraulic shift assist pump was removed. These new units were still called the 400 and 800 series models – but were widely referred to as the ‘mechanical shift' models. This version of the 400 and 800 series were produced up to the year 1985.

OMC Cobra 1986 to 1993

OMC completely re-engineered their outdrives in 1986 and introduced the Cobra model. These new models were available in a variety of motor options; including a 2.3L Ford 4 cylinder (1986-1987), 3.0L Chevy, 5.0L – 5.7L – 5.8L Ford and Chevy small block V8's and the monster 7.5L 460 Ford big block V8 (1987-1988 King Cobra). The new models now used the modern u-joint style drive system.

The early Cobra models had some problems keeping the clutch engaged into the gear in certain instances due to a 3 degree undercut on the top of the clutch dog tooth. The clutch was updated to a 5 degree undercut, and a shift interrupter switch was added along with an updated design for the shift detent.

OMC Cobra / Volvo SX 1993-1998

In 1993 OMC and Volvo entered into a joint venture and began producing a hybrid stern drive. This new design used the OMC Cobra transom plate assembly but was all Volvo engineering beyond that point. This included the Volvo cone clutch outdrive design and heavier duty shifting components which eliminated the clutch dog system. This new system was sold as the Cobra by OMC, and the SX by Volvo. With the introduction of this OMC Cobra/Volvo SX sterndrive hybrid model, also referred to as the ‘cone clutch', the last of the OMC designed sterndrives finished production in 1992.

OMC Outboard Motor Corporation officially went out of business in 1998 when Volvo purchased the rights and their manufacturing facility in Lexington. OEM parts are still being manufactured through BRP (Bombardier Recreational Products). Many OEM parts are still interchangeable with Johnson and Evinrude outboard models; and some outboards still use the identical lower housing as the Cobra model.

Omc 800 Drive

By Doug Alling

Keeping your sterndrive in tip-top shape will add years to its life — and help to keep your boat afloat.

Omc Outdrive Parts Diagram

Giving your sterndrive some attention now can prevent major problems later. (Photo: Volvo Penta)

Sterndrives were first commercially introduced in the early 1960s, and came to dominate the boat propulsion market in short order. The biggest names in the sterndrive game today are Mercury and Volvo with thousands of older Outboard Marine Corporation (OMC) drives still in use but no longer being produced.

When you power up your engine and pull away from the dock, you set in motion a lot of activity at the stern of your boat. You push the throttle, engaging the prop. Power from your engine is transferred to the sterndrive via the drive shaft. Exhaust is pushed from the engine and exits at your prop. All of these functions start inside your boat and end at the sterndrive and require holes through the transom of your boat, at or below the waterline. Three to be exact: One for the throttle cable, one for the drive shaft, and one for the exhaust. And there's only one thing that keeps the water outside the boat from entering those openings — the sterndrive's bellows, those black corrugated rubber things that are clamped to the boat's transom and sterndrive in a place that makes them really hard to see. Perhaps the old saying, 'out of sight, out of mind,' is why bellows become such a big issue when it comes to sinkings. Take away the biggest and most obvious cause of boat sinkings at the dock — hurricanes — what do you think comes in second place? If you guessed sterndrive bellows failures, take a bow.

Ignoring your sterndrive now can cost you money and down time this season.

Take a moment to think about the environment that bellows operate in and the work they are tasked to do. They are exposed to hot and cold, wet and dry, vibration, UV, and marine life (sharp barnacles), and through all that they are expected to stretch, expand, and contract as you tilt and steer your sterndrive. Bellows will wear out — and when they do, they can easily let enough water into the boat to sink it. To keep your sterndrive-powered boat afloat, bellows require inspection and maintenance on a regular basis.

Bellows Inspection And Maintenance

Inspection of the bellows can be accomplished while the boat is out of the water — on a lift, a work stand at the marina, or on its trailer. Keep safety in mind while doing this! Make sure the boat is properly supported and if on the trailer, chock the trailer tires. It is good practice to make sure that there's no way the engine can be started while you are performing your inspection by disconnecting the batteries. The inspection area is tight and will require moving the sterndrive from one position to another — port and starboard, up and down — to access as much of the bellows as possible. The inspection is as simple as taking a close look (a flashlight is required) at the condition of the rubber bellows and their clamps. Are there any obvious signs of cracking? Is the rubber becoming brittle? Is there any rust showing on the bellows? Do the stainless steel clamps show any signs of corrosion? If you spot any marine growth (barnacles, mussels, or the like), they have got to go. Barnacles and broken shells can be razor sharp and your rubber bellows won't stand a chance against them.

Marine growth can be razor sharp and slice open bellows, allowing water into

the boat. Inspect bellows frequently throughout the season. (Photo: Doug Alling)

That's what to look for outside of the boat. Inside the boat, look for any water tracks at the transom pass-throughs and standing water in the bilge. If your bilge pump has been cycling on and off, it's time to inspect the bellows. OK, we've done our inspection and things look good, but keep in mind that all manufacturers have a recommended replacement schedule for your sterndrive bellows. You will most likely find it in your owner's manual and you should adhere to it. If you are unsure or can't find the information, a call to the manufacturer's customer service center is in order. I have dealt with both Mercury and Volvo in this regard and both manufacturers have been very responsive. Even if your bellows inspection shows good results, the manufacturer knows best when it comes to keeping them in tip-top shape and how often they should be changed. Most manufacturers agree that a 5-year-old bellows is living on borrowed time. Not replacing it is inviting water into your boat.

If you poke around the Web, you'll undoubtedly find videos posted on how to change out your exhaust bellows while the sterndrive is still attached to the boat. It can be done — with really small hands and the right tools. But the exhaust bellows is the only one that can be changed while the sterndrive is attached. The other two bellows contain the drive shaft and shift cable, and they can only be changed by removing the sterndrive from the boat and disconnecting those systems. Changing out the exhaust bellows alone goes against one of the first rules that a marine surveyor learns: If something breaks or wears out underwater (a bad cutless bearing, a bent rudder) and there are two or more of them, you must always check them ALL. If you are going to the trouble of changing the exhaust bellows, replace the other two, period.

Beyond Bellows

While you are inspecting or replacing the bellows, take a little time to look over your prop as well. Any visible damage? Any signs of fishing line down there? Fishing line can damage the seals that hold the gear oil in the sterndrive housing. Monofilament line can even reach the melting point when wrapped around a revolving propeller shaft.

Fishing line wrapped around the propshaft can cause the lower unit seal to fail, allowing water to contaminate the oil, which can destroy the unit. (Photo: Doug Alling)

If line is discovered, removal of the prop may be necessary to disentangle it. Take a look at the seal that is just forward of the prop and look for any signs of leaking oil. Then, take a look at the gear oil itself. Is the level OK? If the oil has a milky white appearance, water has entered the sterndrive and the oil will have to be replaced.

Remember, refilling your sterndrive oil is counterintuitive. New oil must be pumped UP into the sterndrive. Never refill from the top oil port or vent hole. If you are concerned about the integrity of your oil seals, your mechanic has a simple method of checking them by vacuum or pressure.

As you run down the list of recommendations your sterndrive manufacturer has outlined for annual maintenance, you'll note that you should be lubricating some important moving parts. Don't overlook the prop shaft, U-joint shaft splines, and steering system cables. One grease gun may not cover the needs of these different applications. Check your owner's manual for recommendations.

If your boat spends much of its time in saltwater, corrosion of the sterndrive becomes a concern. Manufacturers install sacrificial anodes that are designed for your boat's sterndrive and protect the aluminum housing from corrosion. Monitor them closely and replace them when they become half wasted. How often that is depends on the amount of time the boat spends in the water. Check your motor's manual for the location of all of the anodes because some are cleverly hidden, such as under the cavitation plate just above your propeller.

This anode is past due for replacement. Without proper anodes, an outdrive will quickly corrode. (Photo: Doug Alling)

Replacement with aluminum anodes is recommended. Magnesium anodes should only be used if your boat lives in clean fresh water all of the time. Remember that anodes should never be painted. Mercury Marine has gone the extra yard and in some sterndrives has installed the MerCathode system. This is an active or 'impressed' system that actually delivers a small electric current to the sterndrive to counteract corrosion on the unit. The MerCathode derives its power from your boat's battery so, to be effective, your battery has to be charged, and all wires and connections have to be sound. Again, your mechanic should have a simple test to ensure that your Mercathode system is working properly.

Not only should you keep the paint brush away from your sterndrive's anodes, you should steer clear of getting too close to the sterndrive itself. Most bottom paints contain copper and most sterndrives are constructed of aluminum. These two dissimilar metals do not cohabitate well and underwater can turn into a battery of sorts that can lead to corrosion issues. It's important to keep the copper in your bottom paint away from the aluminum in your sterndrive. So, when painting the boat's transom, keep an unpainted area around your sterndrive. Most recommendations are for about one-and-a -half inches of unpainted surface. Use a copper-free, drive-specific paint, such as West Marine's Antifouling Outdrive Spray paint, if the boat is kept in the water full time.

This lower unit cracked over winter when trapped water froze and expanded.

Check for milky oil in the unit before laying up for winter. (Photo: Doug Alling)

And finally, when it comes to storing your sterndrive, it's important to prevent water from entering the exhaust hub of the propeller. Openings that are designed to let the exhaust out can also allow rainwater and snowmelt in. Water will accumulate in the unit's housing if the drive is stored in the 'up' position. In cold weather, any accumulated water in the sterndrive can freeze and, under the right conditions, ice may expand and crack the housing. When putting your boat away for the season, store the sterndrive in the 'down' position or use a sturdy, waterproof cover over the prop to prevent water accumulation in the housing.

Capt. Doug Alling is an American Boat and Yacht Council (ABYC) Master Technician, the principal surveyor for Rum Line Marine Consultants, LLC near Charleston, South Carolina, and a member of the Knox Marine Consultants team.

— Published: July 2014

Seaworthy, the damage-avoidance newsletter, is brought to you by the BoatUS Marine Insurance Program. For an insurance quote, please call 1-800-283-2883 or apply online at BoatUS.com.

To comment on this article, please contact Seaworthy@BoatUS.com

Rebuilt Omc Outdrives For Sale

Sterndrive To Dos

Omc Outdrive Problems

- If you keep your boat on a trailer, inspect your sterndrive's bellows several times each season. Haul out boats kept in the water at least once a year for a complete sterndrive inspection.

- If one bellows needs to be replaced, replace them all.

- Replace the bellows per the manufacturer's recommendations, even if you see no damage.

- Lubricate moving parts at least annually.

- If you get fishing line caught on your prop, inspect the seal in front of the prop for damage.

- If gear oil is milky, replace the seals, as well as the oils.

- Remember to pump gear oil UP when refilling.

- Replace anodes when they are half their original size. Use aluminum for sterndrive anodes.

- When applying copper bottom paint, leave a margin around the sterndrive to reduce the potential for corrosion.

- To keep water from entering the exhaust hub when storing your sterndrive, leave it in the 'down' position or use a waterproof cover.